Michéal Cassidy

CTO – Chief Technology Officer, Irish Manufacturing Research

Data is becoming the lifeblood of manufacturing and supply chain performance. Industry 4.0 (Manufacturing 4.0) is recognition of the age of digital in the manufacturing world.

Ireland is home to some of the world’s front-runners in industry 4.0.

Ireland is also one of the readiest nations to exploit the benefits of industry 4.0. It is time to capitalise on that readiness.

There is a national and global recognition of the importance of this industry disruption. Across the globe, governments are investing in industrial R&D centres to ensure their manufacturing companies are equipped for this disruption.

In Europe, massive funding is committed to large-scale research programmes and knowledge transfer for the benefit of industry. One such example is the Digital Innovation Hubs. This acts as a one-stop-shop for industry to access a vast range of knowledge, expertise and technologies across Europe. Nationally, the Irish government has launched flagship initiatives. These include the Disruptive Technology Innovation Fund to help industry develop and adopt next-generation manufacturing technologies.

Human workers and robots streamlined for increased productivity

The umbrella of Industry 4.0 can legitimately group many technologies. This is because they share a common “digital thread”. Furthermore, this interlinks connected workers, smart products, smart processes and whole supply chains.

Ireland is home to some of the world’s front-runners in industry 4.0. Similarly it is frequently cited as one of the readiest nations to exploit the benefits of industry 4.0. It is time to capitalise on that readiness.

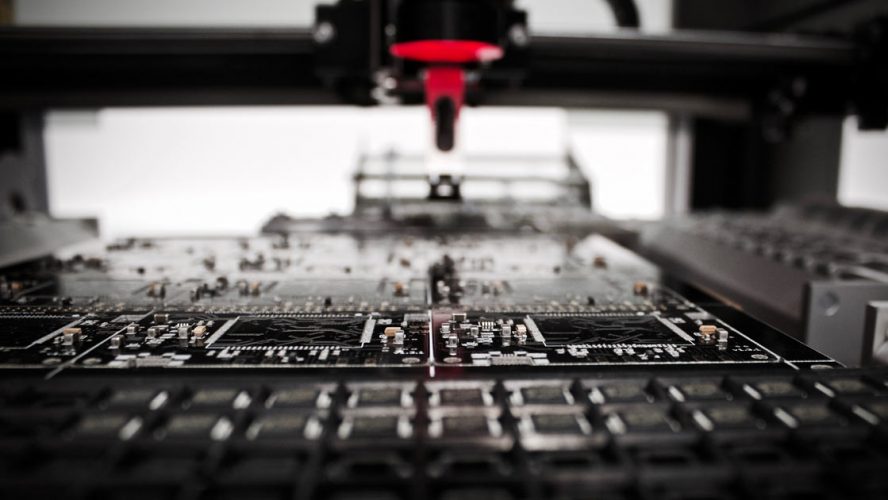

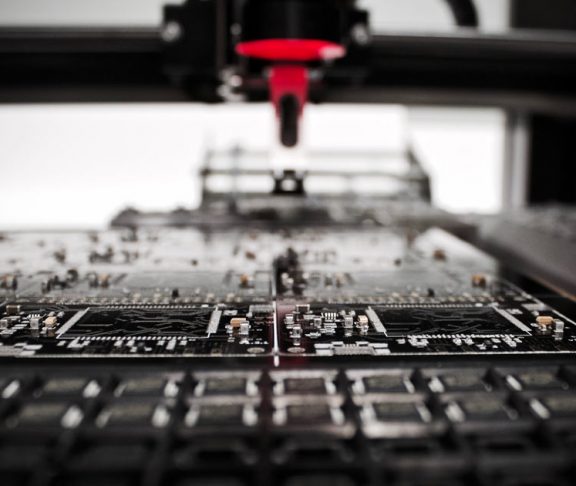

Manufacturing plants are now some of the most advanced workplaces on the planet. This is with engineers and operators augmented with collaborative robots to increase productivity and streamline repetitive work. Also mobile platforms for knowledge sharing and decision making. Finally augmented and virtual reality technologies to enable interaction in both physical and digital domains.

The digital thread also carries through into processes, where digital twins enable real-time monitoring and control of quality and service.

Beyond the walls of the factory, the digital thread connects the manufacturing process to the smart supply chain. Eventually, this chain goes to the customer.

The winners in Industry 4.0 will be the ones who build strong bonds with their consumers. They will respond quickly and in an agile manner to customer demands. Also they will need to meet the highest standard of user experience to secure the strength of their individual relationship.

Consumer-led customisation is the new norm for Industry 4.0 in Ireland

Through digital technologies, consumers now have much more of a direct connection to the manufactured product. Mass customisation is the new reality, from individualised medicine through to personalised garments.

User interaction into the smart supply chain enables a value-add relationship between supplier and customer. Furthermore and increase in brand connectivity and loyalty can be achieved. Additive manufacturing processes, such as 3D printing, enable direct digital manufacturing. Also the ability to customise each part to customer requirements.

Transformation in manufacturing industries is happening at a much faster pace. Conclusively it is imperative that manufacturing companies stay up to date with how these disruptions will impact them.

Measurable business outcomes and long-term competitive advantage must build technology investment. This means that first adopters and fast followers are trying to understand how disruptive technology will bring benefit to their business.

Finally, getting under the hood and discovering which innovations and technologies are going to be significant in Industry 4.0 to each company necessitates that manufacturing industry start today to demystify and de-risk their investments.